Ink Jet Filtration

In order to provide optimized industrial ink jet printing quality, we developed a wide range filtration and separation technology to satisfy the request from all our customers. From printer system to bulk ink production, we do have a wonderful integrity standard solution and what's more, we delicated ourselves into the practical ink jet applicaiton conditions for design innovation and customizable capability. Filtration and separation is extremely important and sensitive process for the entire ink jet chain that should not be neglected. How to make an stable ink formulation is a topic that always in discussion. Colorant particles homogeneity, agglomerates, gels and pulutant from the procession always troubling the ink-jeter. However, solving the problems from chemical aspect, micro-size particles has always been the subject of our research and actually we made great achievements.

-

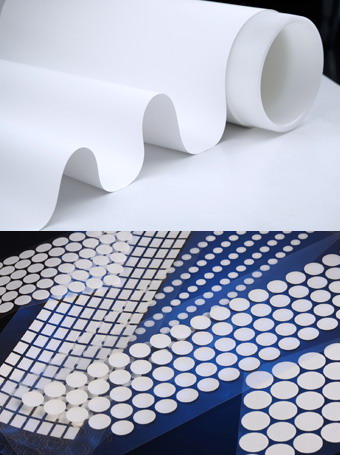

PolyRolled Filter Cartridges

Cobetter PolyRolled Depth Filters are made of continuously rolled microfiber (for a total of 56 layers).The outer layers are constructed of graded pore size while the inner layers are stable pore size. This provides a large filter area and high efficiency.

Highly recommended for pigment-based inks, ceramic inks, and disperse ink jet inks filtration.

-

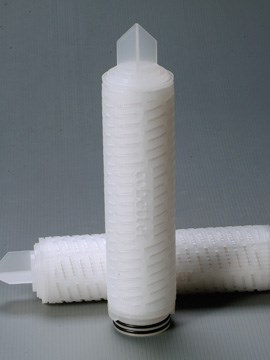

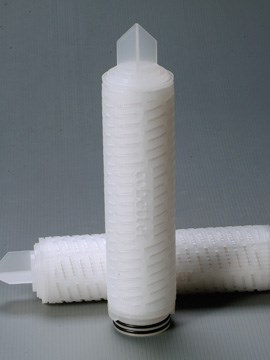

ProtectPP Filter Cartridges

Cobetter ProtecPP Filter Cartridges are made of thermally bonded polypropylene microfibers. This technology forms a rigid fiber structure providing final protection to ink jet inks prior to filling by eliminating the risk of releasing fibers.

-

ExtraButor Hollow Fiber Membrane Degas Modules

Applied in inkjet industry to solve printing problems caused by bubbles and dissolved gases in the ink.

-

Degassing System

Applied to inkjet ink production degassing to provide a complete production degassing integrated system and solve printing problems caused by dissolved bubbles in the ink.

-

Duredunty Filter Cartridges

Cobetter Duredunty Filter Cartridges are made of a double-layer PES membrane and are designed as final filter for dye-based ink jet inks filtration. The double-layer membrane provides great filtration efficiency and can eliminate most of the difficulties encountered by inadequate removal efficiency.

-

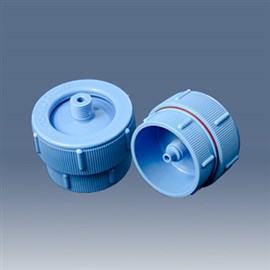

CPC Connector Filter

Our CPC connector is imported with original packaging, no leakage can guarantee filter gas tightness to avoid tube cutting during filter change.

-

SuperPVDF Filter Cartridges

Cobetter SuperPVDF series is polyvinylidene fluoride filter, which is made of vinylidene fluoride filter membrane resistant to organic and inorganic solvents. It can great apply to normal dye-based ink, eco-solvent dyes and color paste filtration. LHPV adopts hydrophilic modified PVDF filter membrane, it can be used directly without wetting.

-

TeflonFlow Filter Cartridges

Cobetter TeflonFlow Filter Cartridges are manufactured with an inherently hydrophobic PTFE membrane that maintains broad chemical compatibility for great corrosion resistance. Narrow pore size distribution ensures the highest retention and flow. It is also available as a hydrophilic PTFE membrane for no pre-wetting requirement when in operation. Recommended for marking & coding inks final filtration.

-

MultiPoly Filter Cartridges

Cobetter MultiPoly Filter Cartridges is an all-polypropylene pleated depth filter cartridges The design adopts depth filter technology for a graded pore size, higher dirt holding capacity, avoids filter surface jams, and eliminates ink contaminants (gels and agglomerates). The graded pore size distribution from coarse (upstream) to fine (downstream) removes particles gradually and extends the filter’s service life.

-

ChemfineN66 Filter Cartridges

Cobetter ChemfineN66 Filter Cartridges are constructed of Nylon 66 membrane and widely used in dye-based ink filtration applications. Nylon66 membrane is naturally hydrophilic with broad chemical compatibilities. DN66 series , which is a double-layer membrane design , is also available.

-

High Flow Last Chance Filter

High flow design to meet high-speed requirement to apply in digital ink jet printer.

Especially for the StarFire 1024 print head users, such as digital ink jet ceramic printer, dyeing machine, advertising printer, UV flatbed printer and so on.

It's mainly used before the print head to intercept the impurities in the inks to avoid it enter into the print head that leads to clogging.

-

AdvanLife® Filter Cartridges

Cobetter AdvanLife Filter Cartridges feature a singlelayer

asymmetric hydrophilic polyethersulpone membrane. They are designed for filtration of aqueous liquids, including dye-based ink jet inks. It’s membrane is characterized by high dirt holding capacity, high flow rate, high efficiency and longer life time.

For regular dye-based ink, AdvanLife Filter Cartridges can be used as final filter for effective particle removal. However,for some special inks that need high-speed printing,

-

High Flow Last Chance Filter

High Flow Last Chance Filter with small size, convenient connection and reasonable design will provide a better protection for printhead, preventing the impurity in the ink supply system and presents long service life in the inkjet

applications.

Ideal for Inkjet coder, advertising printer, textile printer, and so on.

-

Air Filter

Under the influence from the environment of Inkjet equipment, gas fllter has become a necessary filter in large inkjet system to ensure the cleanliness of air intake, so as to best reduce the dust particle pollution of the entire ink supplu system.

-

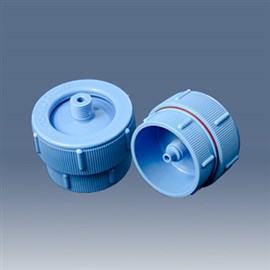

47FH Filter Holder

Cobetter devepoped 47FH filters for pollutans observation. Usually ink manufacturer and printer manufacturer are both facing the problem of how to find out the contaminant and evalutate of the ink, 47FH filter is a perfect test device.