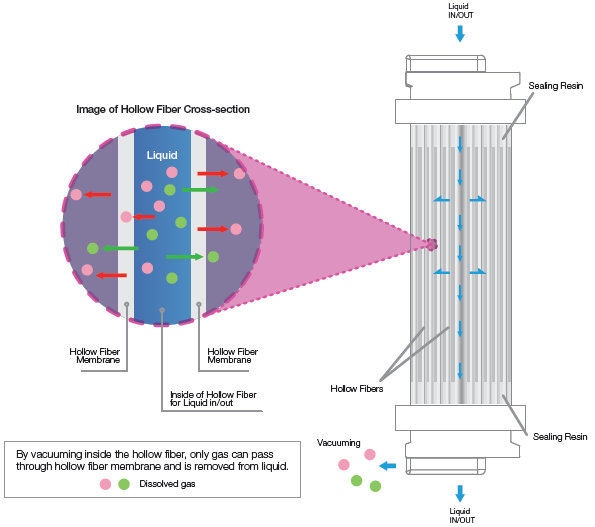

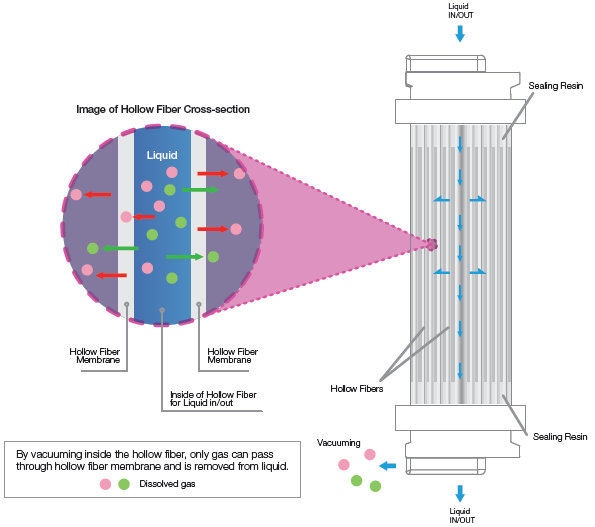

Applied to inkjet ink production degassing to provide a complete production degassing integrated system and solve printing problems caused by dissolved bubbles in the ink.

Features and Benefits

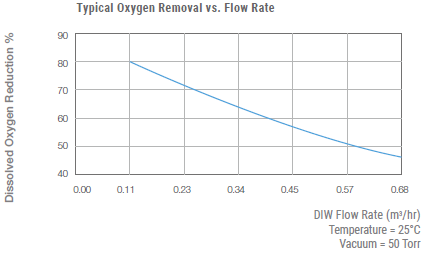

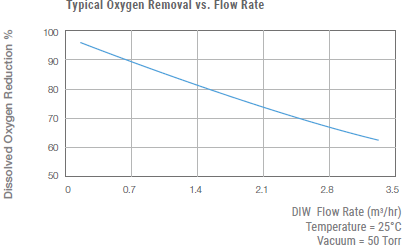

· High degassing efficiency and high removal efficiency for dissolved bubbles

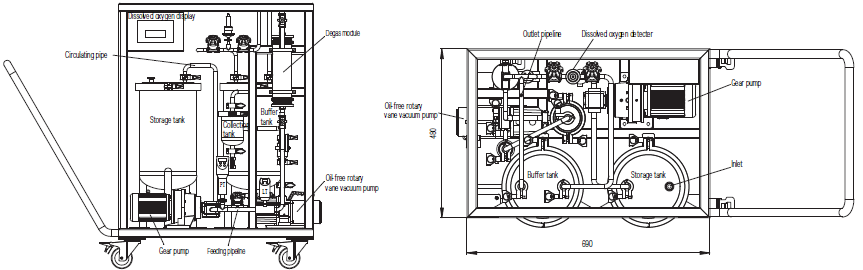

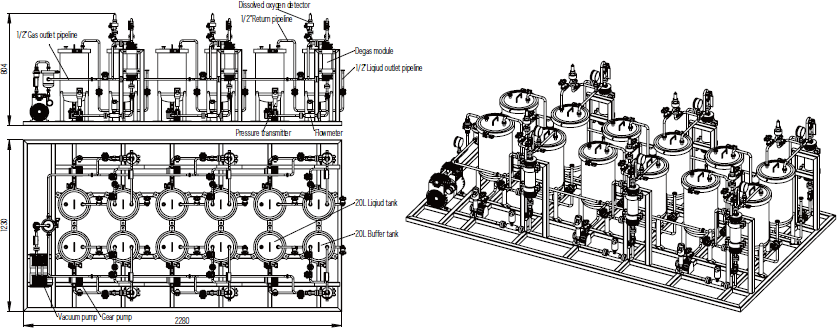

· Integrated system from production to degassing

· Coming with a moveable cart, suitable for customers who prepares a new ink production line

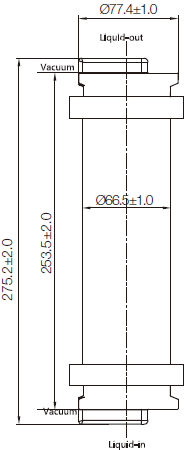

· Highly customizeable system:

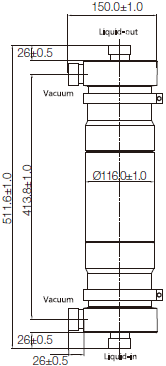

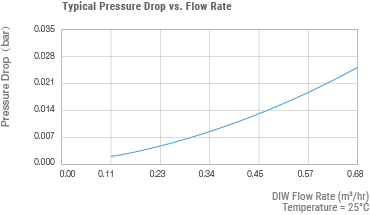

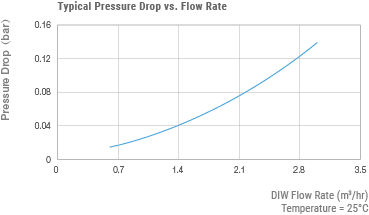

Optional degas module for the actual ink production precess accordingly

· Equipped with dissolved oxygen detector:

Online dissolved oxygen detection and flow rate changeable