Porous Filter in Sensor Application

Cobetter Porous PE Filter.pdf

Cobetter Porous PE Filter.pdf

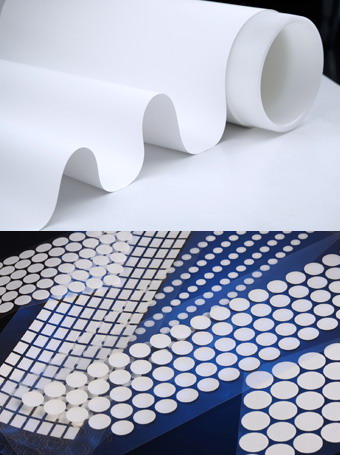

In addition to medical and life science fields, PE sintering is also widely used in automotive, electronics, industrial and other fields, such as a variety of sensors.

| Due to the limitation of its working principle, the humidity sensor detector must be in the form of non-sealed sealing method, which means that it is required to have contact holes or contact windows connected with the outside in the housing so that the humidity sensitive part on the humidity sensor and the humidity in the air can be contacted with each other well. At the same time, in order to prevent humidity sensitive chips from being contaminated by dust or impurities in the air, some protective measures need to be taken. Currently, there are several different sealing methods of humidity sensors, among which the sealing method with external support frame is protected by PE porous sintering.

PE porous sintering is made by customized molds, which has taken full account of space structure to ensure that the humidity sensitive chip and air can fully contact while preventing dust and water droplets from entering into the the device to cause the erosion of precision components. |

Filter Characteristics

- High moisture permeability;

- Dust prevention, Obstruct the liquid;

- Reliable mechanical strength;

- Long service life;

- Accept customized dimensions.

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message