Basic introduction of Arrayforce™ gas-liquid separation membrane contactor

Process water in many industries requires dissolved gases removal or gases injection.

Arrayforce™ gas-liquid membrane contactor provides a highly efficient, energy-saving and environmental friendly gas-liquid separation/mix solution for various industries by utilizing hollow fiber membrane with great hydrophobic property.

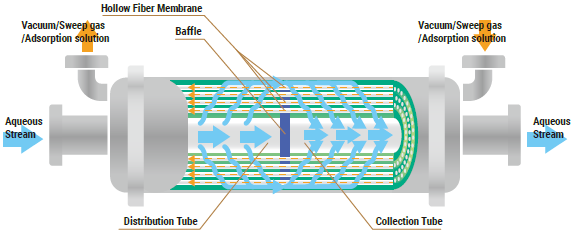

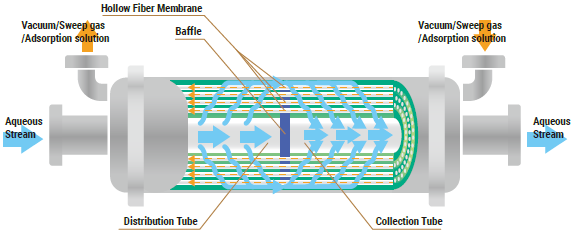

How membrane contactor works:

In typical operation, liquid to be degassed flows outside the hollow fiber. At the same time, vacuum, sweep gas or a certain adsorption liquid go through inside the hollow fiber. There are a lot of micro pores on the surface of hydrophobic hollow fiber, which allow gas molecules pass through, but reject water molecules. Under the force caused by vacuum, sweep gas or adsorption liquid, the gases dissolved in liquid outside the hollow fiber moves continuously through the micropores to the inside hollow fiber, and then is taken away by vacuum, sweep gas or a certain adsorption liquid. In this way, dissolved gases in liquid is removed.

Typical Aplications

Features of Arrayforce™ membrane contactor

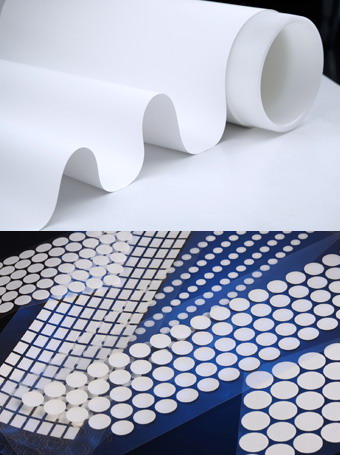

- Great hydrophobic property

The gas-liquid separation function of the membrane contactor is guaranteed based

on its hydrophobic property, but after long-time operation in water, the pores of the

hollow fiber will be gradually infiltrated by liquid. The hydrophobic interface will be

destroyed, and the membrane will lose gas-liquid separation function.

Arrayforce’s special membrane hydrophobization technology ensures the hydrophobic

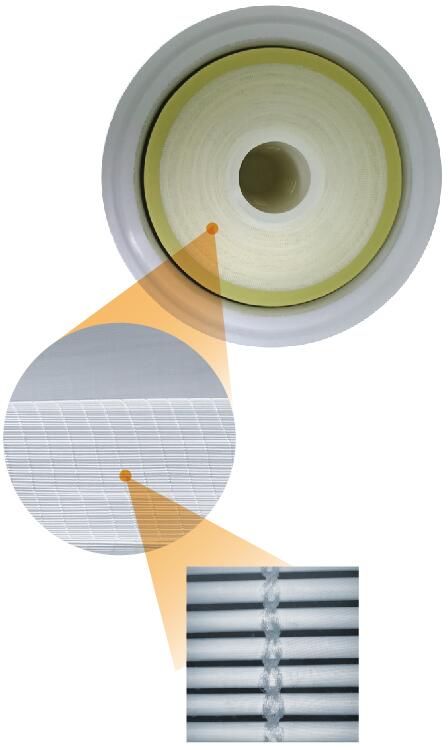

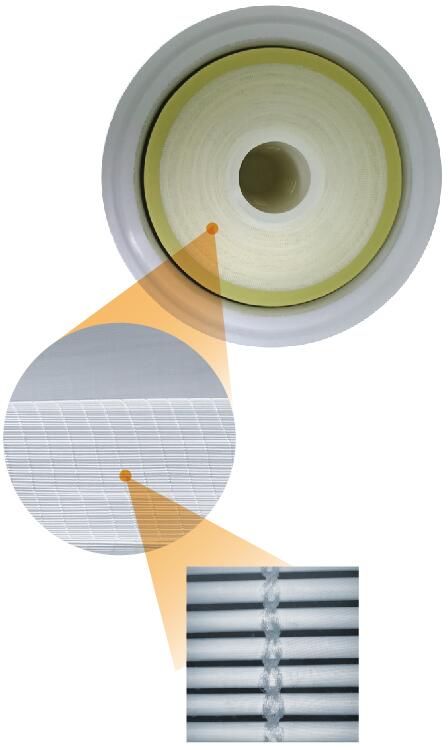

life of membrane long enough for engineering application - Precise hollow fiber arrangement

The hollow fiber knitting process makes hollow fibers into an array, then the

hollow fiber array is rolled up into a housing. The hollow fiber knitting process

expands the effective contact area of the membrane contactor. Besides, each hollow

fiber is fixed, so they will not swing while the water flows through them. In this way,

the hollow fiber will not broke and product water quality can be stable; - High efficient gas-liquid contact

The middle baffle and the central pipe water distribution, make water jet flow

through the hollow fibers, which effectively improves the gas transfer efficiency

between the shell side and the lumen side

| Model | 1×5.5 | 2×6 | 2.5×8 | 4×13 | 6×28 | 8×20 | 10×28 |

Membrane

Area (m²) | 0.1 | 0.35 | 1.41 | 7.66 | 42 | 53 | 130 |

| Flux | 30~300 ml/min | 50~1000

ml/min | 1.67~11.67

L/min | 3.33~50 L/min | 1~10 m³/h | 1~10 m³/h | 6~40 m³/h |

Hollow Fiber Material | PMP/SP | PMP/SP | PP/PMP

/SP | PP/PMP

/SP | PP | PP | PP |

Housing Material | PMP/SP | PMP/SP | PP/PMP

/SP | PP/PMP

/SP | PP | PP | PP |

Working Temperature | 5~70°C | 5~70°C | 5~70°C | 5~70°C | 5~45°C | 5~45°C | 5~45°C |

Max Pressure Shell / Lumen | 7 / 2 bar |

PH Tolerance | 1~14 |

Application Conditions

Hollow Fiber Material | Liquid Material Surface Tension | Liquid Material Viscosity |

| PP PMP SP | ≥60 Dyne/cm ≥32 Dyne/cm ≥27 Dyne/cm | ≤ 50cp ≤ 50cp ≤ 10cp |

Compared with conventional degassers, Arrayforce™ membrane contactors

have the following advantages:

· Expandable: no matter treatment capacity increase or gas removal efficiency improvement, you can make it

through adding membrane contactors in parallel of series ;

· No chemical dosing: no chemical elements increase in water, saving cost of subsequent treatment ;

· Quick start: simple operation process, time required for system stability is very short.