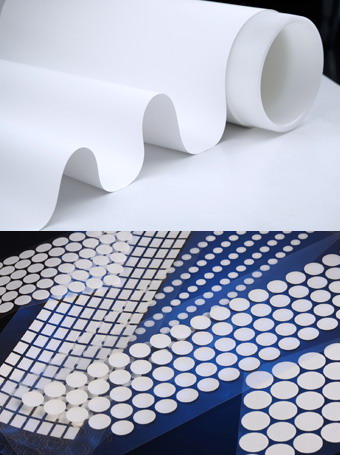

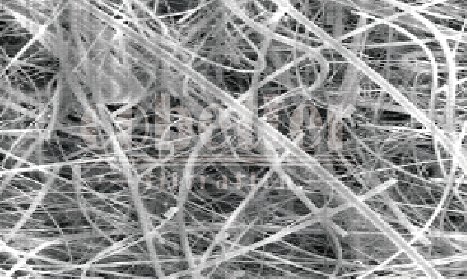

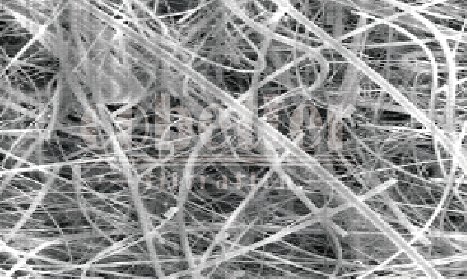

Cobetter GlassFlow Filter Cartridges are made of super fine glass fiber media with a pre-layer constructed of polypropylene for pigment-based ink and paste and dye-based dispersed inks and paste during pre-filtration and final filtration. Glass Fiber Media has an inherently absorptive characteristic that enhances filter retention capability.

Features and Benefits

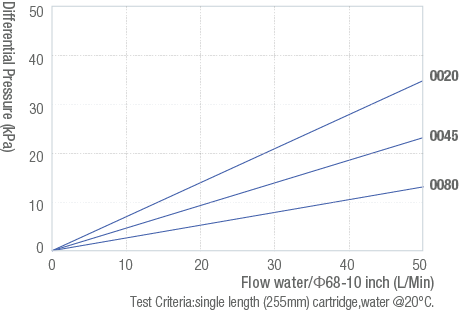

· Super fine glass micro fiber media which provides the benefit of low initial pressure and high removal efficiency (>98%)

· Stiff structure of glass micro fiber media provides high flow rate.

· Built-in polypropylene pre-filtration layer

· Glass fiber media has high dirt holding and inherently adsorptive effect which features its gel removal ability

· Extremely good chemical compatibility

Application

· Super Fine Glass Micro Fiber for Pigment-Based Inks & Paste /

Dye-Based Dispersed Inks / Paste