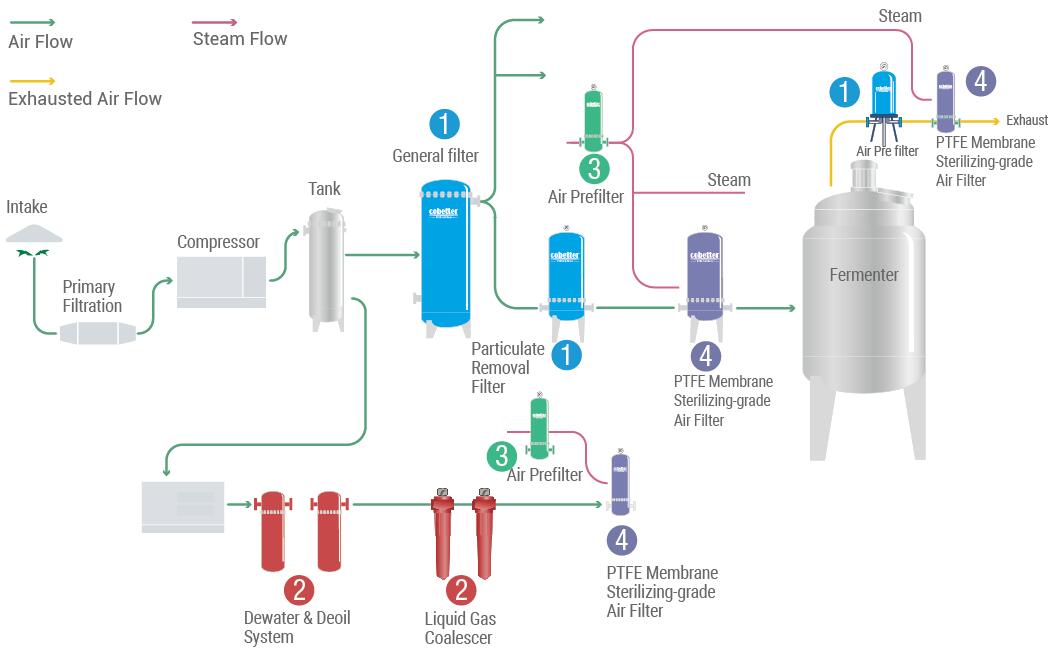

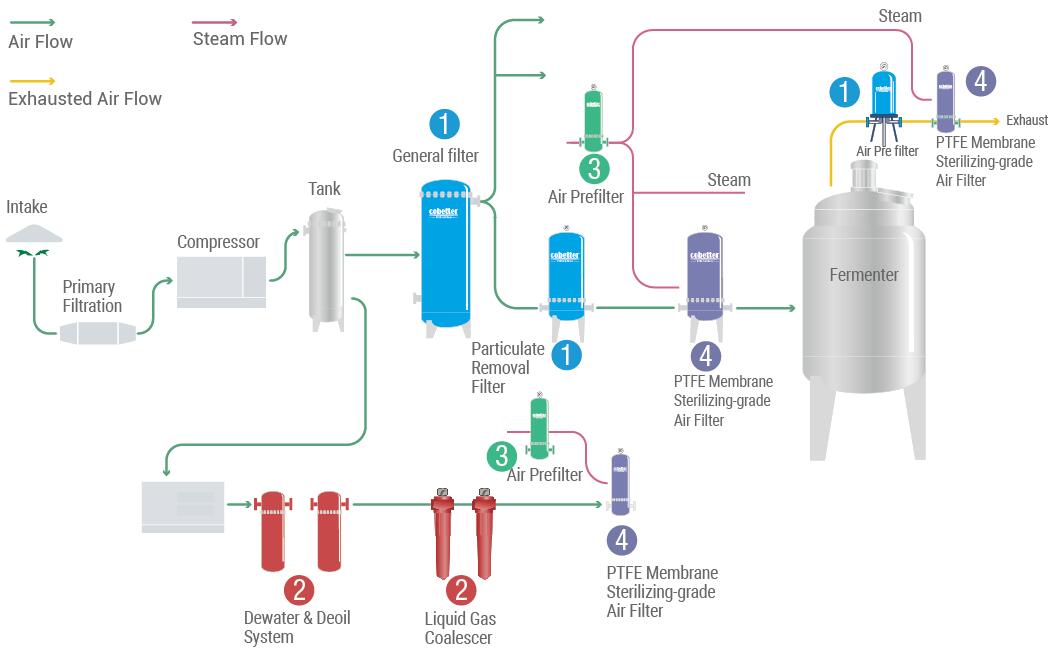

Solutions of Aseptic Air Filtration

Compressed air is one of the most important sources of production power for pharmaceutical companies and is also an important raw material in large-scale aerobic fermentation. Untreated air contains water mist, Oil mist, rust, particulate dust, bacteria and many other impurities that must be removed to ensure safe production and compliance with air requirements. Cobetter offers complete solutions and the best price/performance ratio for your aseptic air systems.

Cobetter provides complete filtration solutions for this application.

Filtration Stage

| Application Description

| Filter |

①-Pre-filtration |

1st Stage of Filtration: as the outside air enters the system, large-scale impurities must be removed so to not affect subsequent stages |

GGFP Series

APT Series

|

②-Oil and Water Removal

System |

For aseptic air system, the toughest contaminations to remove

brought in by the compressor are oil spray and water vapor.

| SOLE Series |

③-Steam Filtration

|

This stage is used to remove impurities that could cause damage

to the downstream filter. |

CSSC Series

PSSF Series

|

④-Sterile Gas Filtration |

This stage is the core component of the aseptic air system.

It must work regardless if the environment is damp or dry. |

GPFL Series

HSGPF Series

|