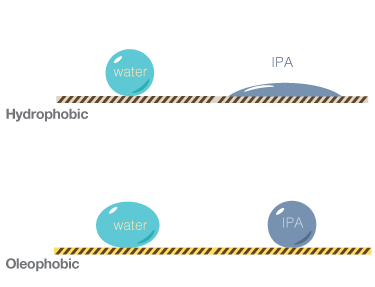

Oleophobic membrane is a super-hydrophobic PTFE membrane modified by hydrophobicity surface treatment (molecular level). Cobetter Oleophobic PTFE membrane meets Oil Rating 8 (AATCC 118), staying hydrophobic against low surface tension liquids like lipids and ethyl alcohol/methyl alcohol.

| Cobetter hydrophobic PTFE membrane is qualified for common venting cases, but for most of chemotherapeutic medicine infusion venting applications, to secure long duration of non-wetting status and maintain venting function, the vent membrane is required to have a lower surface tension than that of contacting liquids, and Oleophobic PTFE membrane is therefore introduced because of its super low surface tension. |

Oleophobic option is necessary for chemotherapeutic medicine delivery venting (Alcohol Repellent), and is also recommended for common venting applications because it offers a longer hydrophobic lifetime, a more secured non-leakage promise, and a higher product safety.

Surface Tension Comparison of Various Membranes and Solvents

| Material | Surface Tension (Dyn/cm, 20℃) |

| Hydrophilic PES Membrane | >85 |

| 5% NaCl | 77.5 |

| Pure water | 72.8 |

| Hydrophobic PTFE Membrane | 31 |

| Chloroform | 27.1 |

| Acetone | 23.7 |

| Methyl Alcohol | 22.6 |

| Ethyl Alcohol | 22.3 |

| Oleophobic PTFE Membrane | 19 |

Note: 1Dyn/cm=1mN/m

Ultrasonic, Heat, RF Welding, Mechanical, Inserting Molding

Autoclave,Ethylene Oxide, E-Beam, Gamma Irradiation

0.02, 0.03, 0.05, 0.1, 0.2, 0.45, 0.8, 1.0, 2.0, 5.0, 10.0

Filtration Efficiency ≥99.99999% Brevundimonas diminuta

Air Flow Rates Gurley 17-49sec

WEP(60s) >450 KPa

Thickness 280-440μm (Supported)

- IV Filter Vent

- Transducer Protector (TP)

- Bacterial Air Vent

- Sensor Protection Cover

- Package Vents

- Drip Chamber Spike Vent

- Dispensing Pin

- Urine Meters/Bags

- Ostomy Pouches

Polyester, Polypropylene, Un-supported

Roll, Sheet, Disc, Adhesive Backing, Customization

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message