Porous Filter in Medical Application

Cobetter Porous PE Filter.pdf

Cobetter Porous PE Filter.pdf

Suction Canister

| In clinical treatment process, especially in operation rooms and emergency rooms, where patients' blood, sputum, human tissues or body fluids need to be removed, suction canister are usually used to absorb and preserve the waste medical liquid by using the principle of negative pressure, so as to eliminate the phenomenon of secondary pollution in hospitals.

The filter that Connects negative pressure piping and the bottle requires the self sealing function. As the core component of waste liquid suction canister, the self sealing PE sintered filter can provide the functions of ventilation and filtering when not contacting with waste liquid. Delivering negative pressure can make clinical waste liquid pumped into bottle through hospital’s suction liner system. At the same time, it also can filter out dust, bacteria and other harmful substances, which prevents the cross infection. However, when the bottle is full and the self sealing PE sintered filter contacts with waste liquid, the filter instantly completes the self-sealing, blocking the flow of all liquids and gases. Meanwhile, it will provide a reliable pressure resistance to prevent harmful substances from entering the hospital’s suction liner system to cause secondary pollution. |

Cobetter’s self sealing PE sintered filter for suction canister can satisfy the clinical ultra-high air flow requirement. At the same time, it ensures that the filter can complete self-sealing in a very short time and is with ultra-high level of bacteria retention efficiency.

Typical Parameters

- Bacterial Filtering Efficiency: 99.99%

- Virus Filtering Efficiency: 99.99%

- Air Flow Rate: 5L/min @ 20inchHg

- Resistance to Water Pressure: ≥70kPa

The filter with activated carbon function can also be provided, which has three functions of ventilation, anti-overflow and odor absorption.

Cobetter provides customized services. We can customize the filter and develop mould according to the product size required by customers. The general mold development period is as followings:

Sample mould (Only used for early period of proofing and verification) Period: 2.5 weeks.

Mass production molds (Used for batch production and supply after verification) Period: 3~4 weeks.

IV Catheter

| The use of IV catheter can reduce patients' pain caused by repeated intravenous puncture and their fear and anxiety of injection. ,Meanwhile, IV catheter is also convenient for clinical medication and rescue medication for urgent and seriously ill patients, through which workload of nurses can be reduced. Therefore, IV catheter is widely used in clinical practice. The core of the IV catheter consists of a flexible catheter/cannula that can be retained in the blood vessel, and a stainless steel puncture needle. When using the IV catheter, the catheter and the needle will be punctured into the blood vessel together. After all the catheters have entered into the blood vessel, the needle should be withdrawn back and only the soft catheter will be retained in the blood vessel for infusion treatment. |

|

There are various of different kinds of IV Catheter. Y type and pen-holder type (straight type) are commonly used in hospitals. Self sealing PE sintered filter plays an important role in penholder type IV Catheter. As we know, the air is not allowed to enter into the patient's blood vessels during infusion. Due to the unique structure design of pen-holder type IV Catheter, it adopts the operation mode of first puncture and then connecting the infusion device pipeline, which requires separate exhaust. Self sealing PE sintered filter is usually assembled at the end of the IV Catheter. When the needle is inserted into the blood vessel, which will cause the blood to flow back. At this time, the air will be discharged through the filter. When the air is completely discharged, the filter will complete self sealing when it contacts with blood, which will prevent medical care personnel from getting the secondary infection that is caused by blood leakage. Meanwhile, the self sealing filter also isolates the contact between the outside air and blood.

Thanks to the Cobetter’s strict and refined production quality management system, our filter has the characteristics of good bio-compatibility, high accuracy, small deviation, large and stable air flow, fast and complete self-sealing. We also accept customer’s customization requirements.

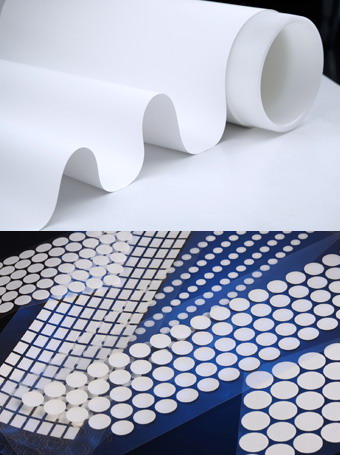

Dialyzed Powder Bag

| PE porous sintered filter can be used not only for air filtration, but also for liquid filtration. Although the material is naturally hydrophobic, the filtration of solution can be realized under certain external pressure by controlling the change of pore size. Cobetter’s hydrophilic modification technology can make the filter have the ability to filter by relying the gravity of the liquid itself.

Dialyzed powder bag is a common application of PE porous filter in liquid filtration field. A dialyzed powder bag is equipped with two filter elements and they are refined filter and coarse filter. The coarse filter is connected with the water inlet, which can filter impurities in the water when mixing liquid and prevent the sodium bicarbonate powder in the bag from spilling. So, the accuracy requirement of the coarse filter is slightly lower. However, the refined filter is placed inside the bag as the outlet. When the purified water enters into the bag from the coarse filter and contacts with the sodium bicarbonate powder to form a saturated sodium bicarbonate solution, the refined filter will retain the powder that has not been completely dissolved to prevent it from entering into the downstream pipeline. |

As PE porous sintered filter has a lot of advantages such as good biocompatibility, simple assembly without welding and low cost, it is a very good choice to use this for some applications such as dialysis dry powder bags.

Cobetter selects ultra-clean PE raw materials, produces in the clean workshop, and strictly controls the in-batch difference and inter-batch difference of products, provides filters with high dimensional accuracy and consistency. At the same time, Cobetter’s workshop is also equipped with high-end light and shadow inspection equipment to prevent products with burr and flecks from flowing out.

Filter Characteristics

- High and stable filtration rate;

- Fast flow rate;

- High dimensional accuracy;

- Less burr and flecks.

Medical Devices |  |  |  |

|

|

|

| To be continued ... |

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message