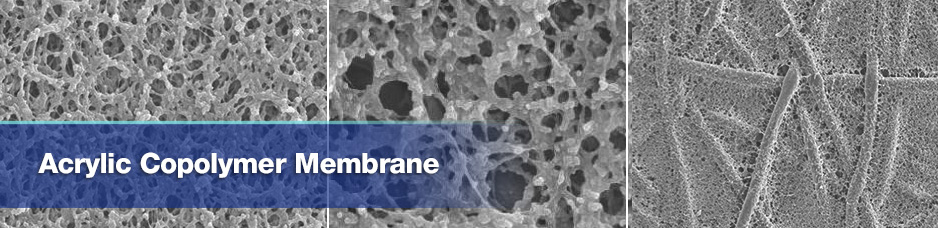

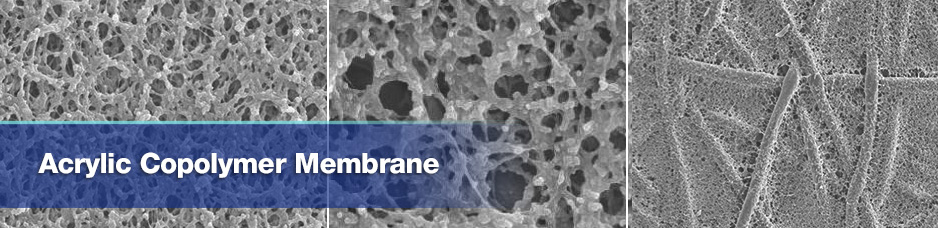

Acrylic Copolymer Membrane

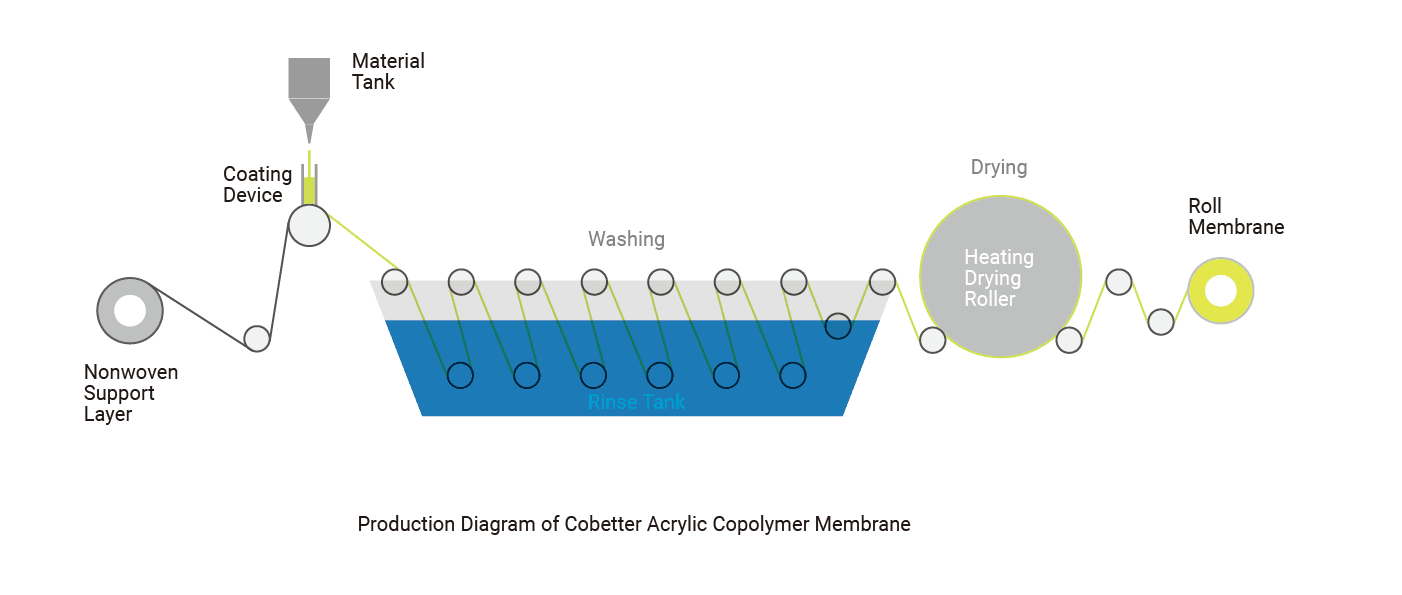

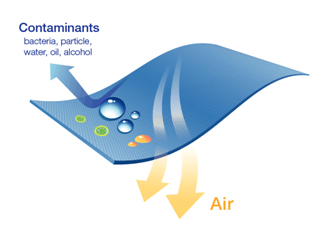

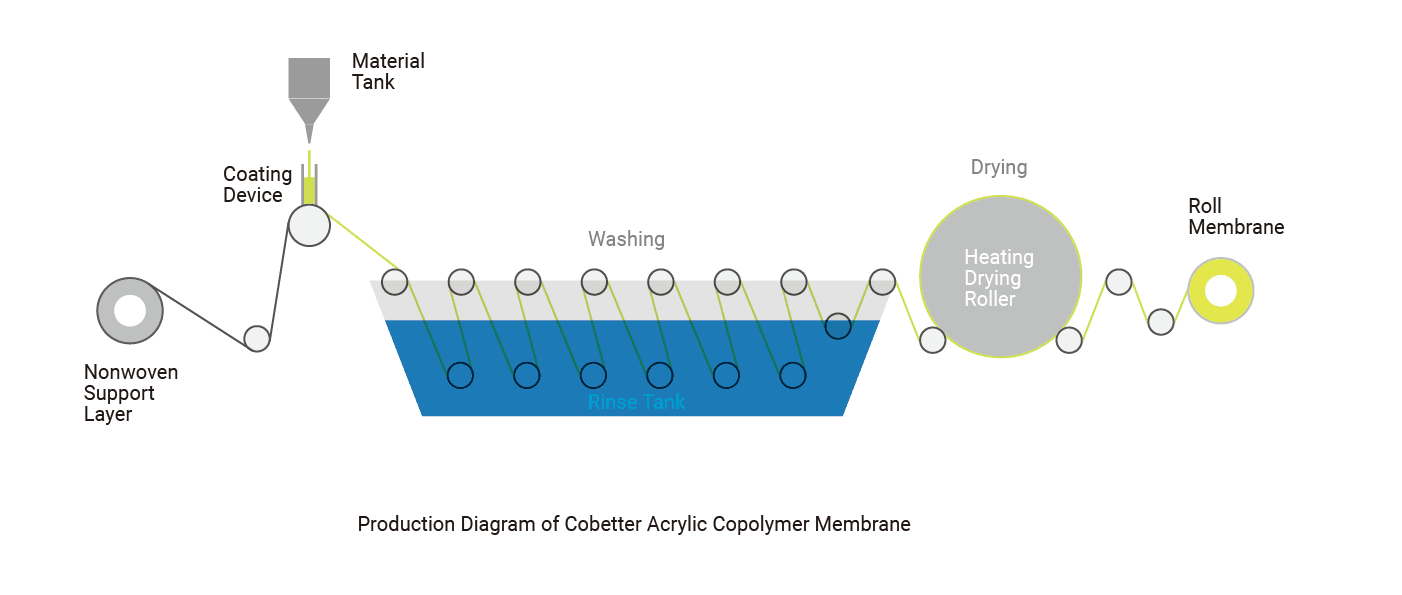

Cobetter Acrylic Copolymer Membrane is acrylic copolymer membrane cast on nonwoven nylon support. It is both hydrophobic and oleophobic material with excellent air permeability and broad chemical compatibility, the oil rating could be up to 8 grade (AATCC 118-2013). Non-wettable by most low surface tension liquids and high air flow rate makes it an ideal material for a variety of air venting applications, which has same good performance as Versapor*.

| Benefit from the unique casting process and robust support layer, acrylic copolymer membrane is one of the most durable materials, which makes it compatible with multiple welding methods, including ultrasonic welding, torsional welding, thermal welding, RF welding, insert welding etc. The special construction of the membrane makes the welding easier, both sides could be welded without distinguishing. The simple handling feature improves the labor efficiency. |

Cobetter Acrylic Copolymer membrane withstands Ethylene Oxide(EtO), E-Beam, Gamma Irradiation (Up to 50KGY) and steam sterilization, providing compatibility to the most stringent sterilization requirements in medical applications. In addition, our membrane complies with United States Pharmacopeia(USP) Biological Reactivity Tests,In Vivo<88>for biosafety and is non-cytotoxic.

This membrane has good compatibility with a wide range of housing/plastic materials: High Density Polyethylene(HDPE), Low Density Polyethylene(LDPE), Polypropylene(PP), Acrylonitrile Butadiene Styrene(ABS), Polycarbonate(PC), Polymethyl Methacrylate(PMMA) etc. Due to the characteristics of non-woven nylon support, it is also suitable for high-frequency welding of PVC, EVA and other soft bags films. The peel strength after welding is superior to any other membranes, and it has unique advantages in the special application of urine bag and drainage bag.

*Versapor is a trademark of Pall Corporation.

PFOA Free

Cobetter can supply PFOA free membrane filter that do not contain Perfluorooctanoic acid (PFOA), its salts and PFOA-related substances, which comply with relative regulation requirements in European REACH EU2017/1000, EC1907/2006 (REACH), and POP EU2020/784.

Features and Benefits

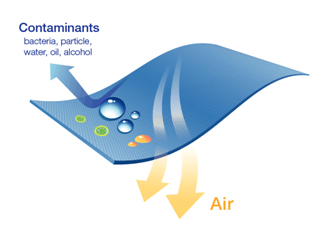

• Robust air/ gas filtration and venting performance over a broad range of operating conditions.

• Strong Physical Integrity, resistance to low surface-tension fluids.

• Reduce the risk of bacterial/particulate contamination.

• Flexible welding with both sides.

• Ideal choice for medical device venting and liquid barrier application.

Application

• IV Filter Vent

• Urine meters / bags

• Ostomy pouches

• IV spike

• Dispensing pin

• Suction canisters

Specification

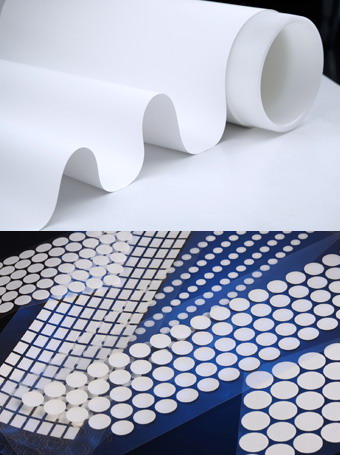

Acrylic copolymer membrane on nonwoven nylon support

Available Pore Size

0.2μm, 0.45μm, 0.8μm, 1.2μm, 3μm, and 5μm

Biological Safety

Meets USP<88>, for class VI-121℃ plastic

Sterilization

Ethylene Oxide, E-Beam, Gamma Irradiation, Steam Sterilization.

Available Format

Roll , Sheet , Disc , Customization.

| Compatible Materials / Methods | Acrymer Copolymer Membrane |

| Housing / Plastics Materials | HDPE, LDPE, PP, ABS, PC, PMMA, PVC, EVA etc. |

| Welding Methods | Ultrasonic welding, Torsional welding, Thermal welding, RF welding, Insert molding etc

|

| Sterilization Methods | Ethylene Oxide, E-Beam, Gamma Irradiation, Steam Sterilization. |

For technical data sheet or application inquiry, you are more than welcome to contact our sales representative by sales@cobetterfilter.com or leave a message